MAINTENANCE AND REPAIR

Rotary Disc Mower is produced by full of quality.So this machine will not need so much maintenance and repair after working with the machine.

Take care about the items that is written below for maintenance and repair:

• Cleaning, lubrication or adjusting of the implement,driven by the P.T.O shaft can be done when the connection and the engine are switched off and the ignition key is pulled out.

• Maintenance and repair must be done after the shaft and machine is disconnected from the tractor.

• It is easy to repair and make maintenance to the Rotary Disc Mower.

• Put the machine in a closed area after work, lubricate the parts and take care against rust.

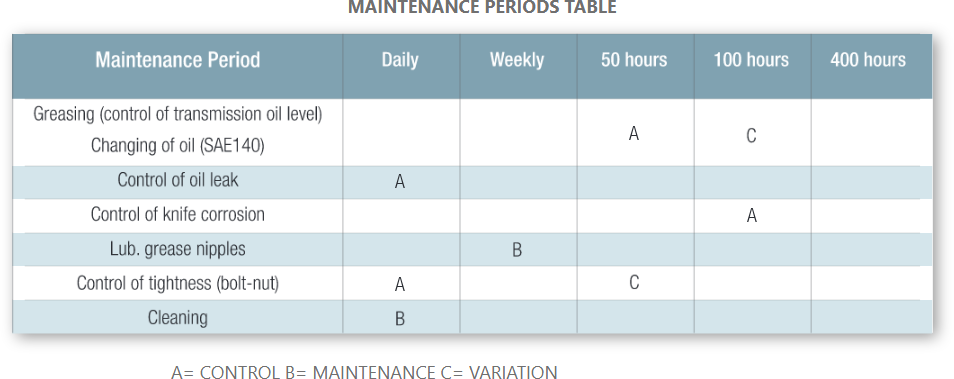

• Control the nuts and screws every day to see if they are tightened enough. If not tighten them.

• Change the broken and weared parts.

• Choose the suitable parts while making maintenance. The parts must be safety.

• Use adequate tools and gloves during repairs,mainteance and cleaning.

• Lubricate the grease nipples periodically as shown in Pic.18-19.

• Use original spare parts.

• Control the gear box oil level in each 50 hours of work.Change the oil of the gear box after controlling the oil level in the period of 100 hours work.Use SAE 140 oil in the gear box.Fill 5 litres of SAE140.

• If you perform any maintenance on the lifted implement,always secure the implement by a suitable holder.

• Call ALPLER technical service for the maintenance of the machine.

PDF Download

PDF Download