MAINTENANCE AND REPAIR

Drum Mower is produced by full of quality. So this machine will not need so much maintenance and repair after working with the machine.

Take care about the items that is written below for maintenance and repair:

• Turn engine off when adjustment, service and repair work is to be done.

• Do not work under the machine without safe support.

• Retighten all screws after the first hours of operation.

Cleaning of machine parts:

• Do not use high pressure water for the cleaning of bearing and hydraulic parts (Figure 1).

• Danger of rust.

• After cleaning, grease the machine according to the lubrication chart and carry out a short test run.

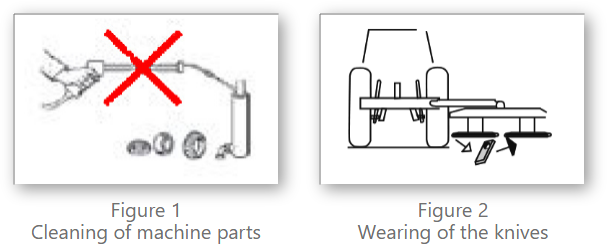

• The knife has cutting edges at both sides. Therefore it is possible as soon as one edge is blunt to take the knives and use it on the next drum (Figure 2).

Replacing the knives:

• Support the lever against the lower edge of the drum and press the flexible holder on the lower end of which is fixed the cutter on the pin.

Remove the damaged knives and apply a new one, at the same time the rests of fodder around the pins of the knife holders, eventually from the inner space of the discs. Remove the lever and check whether the pin of the holder has returned to the initial position and whether the knife removes the knife revolves freely on the pin (Figure 3).

• Check the wearness of the knives more frequantly on stony ground.

• Check normally every 100 hours.

• Check the mowing blade mountings more frequently when mowing on stony ground.

If mowing disc is worn through close to the mowing knives proceed as follows:

• Remove bottom disc.

• Undo nuts on knife mountings.

• Tighten bolts frimly and check aftersome hours operation.

• Lubricate with grease before starting work and every 8 hours worked.

• Before any extended period of non-use, clean and lubricate drive shafts.

• For winter working, grease the tube guards, to avoid them freezing together.

• Gear oils according to operating instructions-however at least once a year.

• Take out oil drain plug, let run out and duly dispose waste oil.

• Before garaging the machine (winter seaseon) an oil change and greasing of all lubricating points has to be done. Unprotected metal parts outside (joints e.t.c.) have to be protected against corrosion.

The oil in the gear-box is 15-16 kg.

PDF Download

PDF Download