PERIODIC MAINTENANCE AND REPAIR OF MACHINE

SPECIAL SAFETY INSTRUCTIONS

• Place machine on the ground, stop the engine, pull out the ignition key and disengage the PTO shaft always before proceeding to periodic repair, maintenance, cleaning etc.

• Please make sure that ground is dry after cleaning the service area where maintenance and repair is carried out. Don’t delay to check power outlet and electrical appliances.

• If machine is lifted for maintenance and repair, only recommended lever and appropriate ropes, chains etc. should be used.

• Machine should be stored on a rigid and flat ground in a dry, closed place. Moreover It should be supported and secured with wedges against the risks of rolling and rollover

• Use appropriate tools while determining the leaking points during periodic maintenance and repair in order to prevent the accidents and injuries!

Hydraulic oils under high pressure may penetrate the skin and cause severe injuries in case of leakage! In case of injury seek to medical assistance immediately! Infection risk is available!

GENERAL

• Call authorized service or manufacturing firm’s technical service for your all questions on the maintenance and repair of your machine!

• Keep first aid kit and fire extinguisher available in the service area where maintenance and repair are carried out!

• Spare parts to be used in the repair of treated machine must be original spare parts in accordance with technical specifications recommended by manufacturer and repair should be carried out safely with appropriate tools! Otherwise manufacturing firm can’t be hold responsible for the accidents and injuries which may occur!

• Machine should be stored on a rigid and flat ground in a dry, closed place. Moreover It should be supported and secured with wedges against the risks of rolling and rollover!

• Please make sure that equipments and tools used aren’t left on the machine following your applications on the machine!

• Safety systems on machine should be controlled regularly and the ones which have lost their functions should be replaced!

• Only use original spare parts, it prolongs the life of your machine!

• Follow the instructions on periodical maintenance and repair unconditionally in order to ensure that machine operates perfect and minimize the wearing!

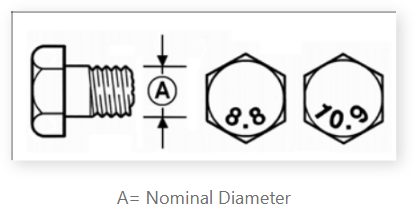

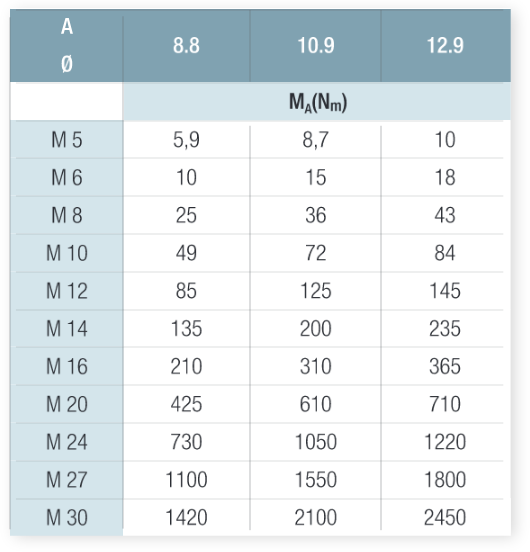

TIGHTNESS CONTROL OF BOLTS AND SCREWS

Check all screws and bolts and tighten the loose ones following first 3-hour operation and then periodically (approximately once in 50 hours). Tightening Moment of Bolts and ScrewsMA

LUBRICATION

Places on the machine where grease nipples are located and points which should be greased once in 30 hours are shown in details in Picture 1-7.

Periodic lubrication shouldn’t be delayed and performed regularly in order to ensure that machine operates perfect and minimize the wearing and prolong its operating life!

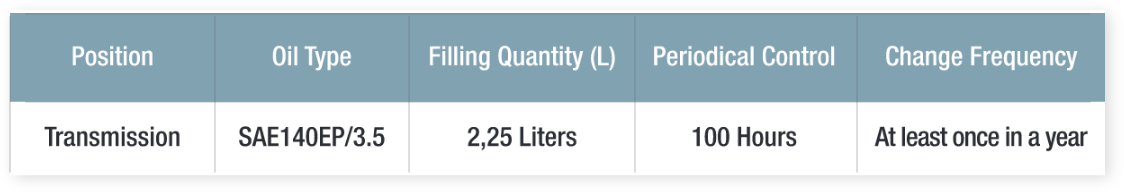

Check the oil in transmission as shown in Pictures 8 and 9 before running the machine. Oil level should be at the level of oil plug (2) as shown in Picture 9.

Check the oil in transmission as shown in Pictures 8 and 9 before running the machine. Oil level should be at the level of oil plug (2) as shown in Picture 9.If oil level decreased, replenish it with SAE140EP/3.5 (1) (Oil No. 141) (as a standard) from oil filler plug (See Picture 8).

Drain and change the transmission oil from drain plug (3) for the possibility of contaminated oil at least once in a year (See Picture 9).

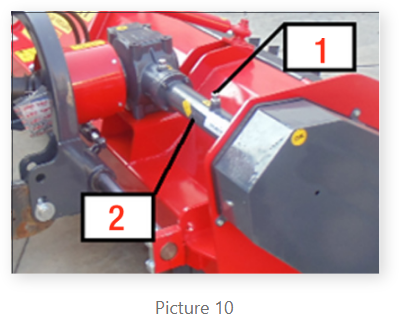

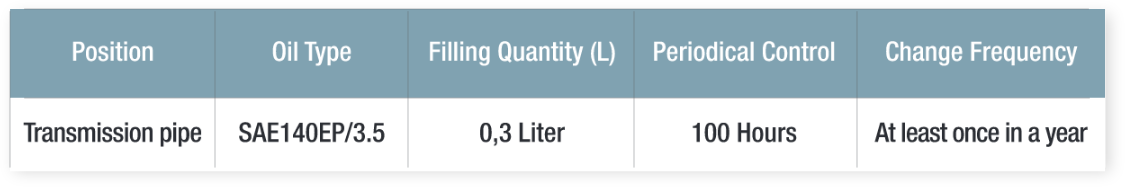

Check the oil in transmission pipe as shown in Pictures 10 before running the machine. Oil level should be at the level of oil plug (2). If oil level decreased, replenish it with SAE140EP/3.5 (1) (Oil No. 141) (as standardized) from oil filler plug.

Check the oil in transmission pipe as shown in Pictures 10 before running the machine. Oil level should be at the level of oil plug (2). If oil level decreased, replenish it with SAE140EP/3.5 (1) (Oil No. 141) (as standardized) from oil filler plug.

P.T.O SHAFT PERIODIC MAINTENANCE

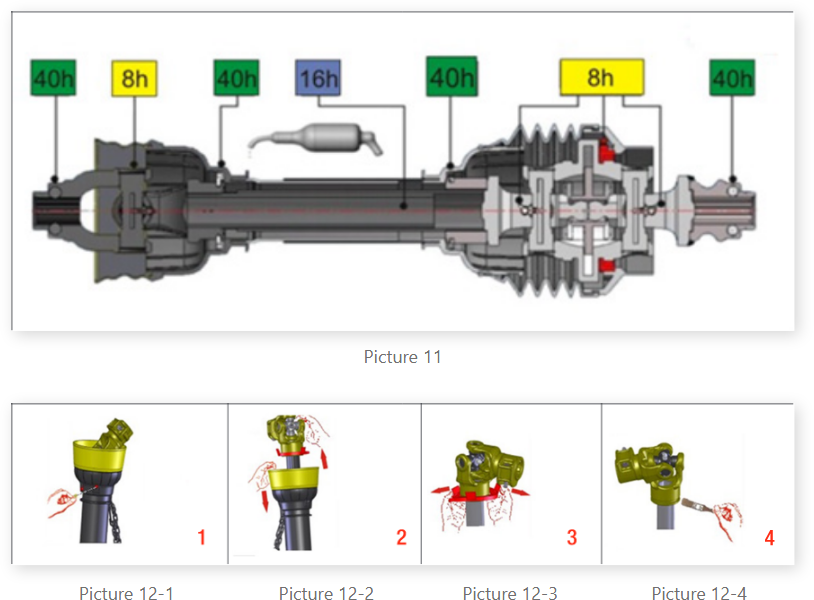

Lubricate the shaft with grease at the points shown in Picture 11 periodically at the prescribed hour(h) frequency.

• Push the ring groove with a screw driver at the points shown in Picture 12-1.

• Push the ring groove with a screw driver at the points shown in Picture 12-1.• Jacket going out as shown in Picture 12-2 is drawn to arrow direction.

• Ring as shown in Picture 12-3 is drawn to arrow direction and removed from the channel.

• Lubrication is done while the ring is separated from the channel as shown in Picture 12-4.

PDF Download

PDF Download