Power Transmission With P.t.o Shaft

• Please use the original shaft recommended by manufacturer! Manufacturing firm can’t be hold responsible for the accidents caused by the use of another shaft!

• Make sure that shaft is mounted and secured appropriately!

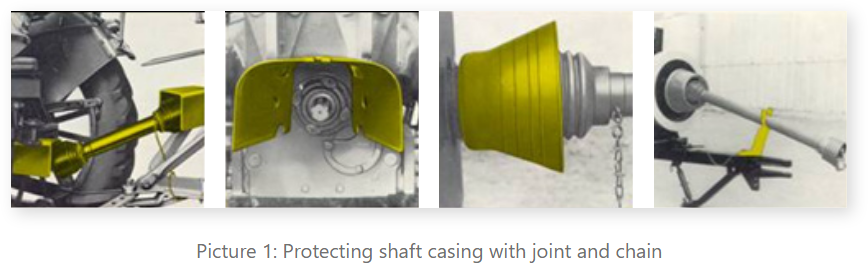

• Affix the shaft and tractor’s tail spindle also and protective pipe and protective funnel of transmission output shaft at the machine and position them in accordance with the rules!.

• Protective sheet for tail spindle and protective pipe of transmission output shaft and shaft joints should be enclosed up to the midline from both sides!

• Make sure that shaft is hanged on as recommended in transport and operation modes!

• Make sure that protective pipe covering is affixed to contain the joints and secured by a chain for stability! (See Picture 1).

• Place machine on the ground, stop the engine and pull out the ignition key and disengage the PTO shaft always before attaching and detaching the shaft.

• When the shafts with overrunning clutch are used, the said clutches should be suited at machine side.

• Check whether RPM and rotation direction of PTO shaft are suitable for the machine and ensure that it reaches appropriate RPM for machine before running PTO shaft!

• Make sure that there is no adult, children or living creature within the unsafe limits around the machine before running PTO shaft!

• Ensure that there is no one at the operation site of PTO shaft

• Make sure that it doesn’t run when the angle of deviation which is the angle between the axis of tractor’s tail spindle to which shaft is connected and tail spindle of machine’s transmission through which power is transmitted increases or where unnecessary (Angle of deviation mustn’t exceed 30º!).

• The fact that machine may operate for a while after stopping PTO shaft. Don’t be close to the machine at that time. When rotation stops completely, you may approach the machine!

• Repair all failures of shaft before running machine!

• Adjustment, cleaning, maintenance, lubrication etc. for the machines driven by PTO shaft may be performed only when the engine is stopped, ignition key is pulled out and PTO shaft is disengaged!

• When shaft is not used or disconnected, shaft should be fitted only on tow bar or any holder prescribed on machine for this purpose. In this way shaft is prevented from touching ground and being damaged!

• When tail spindle of shaft is disconnected, install tail spindle cup and cover always!

• Insert the side bearing tractor Picture to tail spindle while attaching PTO shaft!

• Covering distance for shaft clearance should be at least 10-15 cm for 1-meter shaft!

• Periodical maintenance and lubrication for jointed shaft shouldn’t be neglected and should be performed regularly.

PDF Download

PDF Download